Activity-based management from https://www.accountingtools.com

May 07, 2018

Activity-based management (ABM) is used to determine the profitability of every aspect of a business, so that those areas can be upgraded or eliminated. The intent is to achieve a more fine-tuned organization with a higher level of profitability. The information used in an ABM analysis is derived from activity-based costing, where general overhead costs are assigned to cost objects based on their use of activity drivers. A cost object is anything about which a business wants to collect cost information, such as processes, customers, products, product lines, and geographic sales regions. Several examples of how ABM can be used are:

- To determine the total profitability of a customer, based on its purchases, sales returns, and use of the time of the customer service department.

- To determine the total profitability of a new product, based on its sales, warranty claims, and repair time required for returned goods.

- To determine the total profitability of the R&D department, based on the funds invested and outcome of new products developed.

The information derived from an ABM analysis can also be carried forward into a company's forecasting models and budgets, which gives management a better idea of the future prospects of the business.

The trouble with ABM is its underlying assumption that all of the benefits and costs of a cost object can be translated into monetary terms. For example, the outcome of an ABM analysis might lead management to the conclusion that the workplace should be downgraded to a lower-grade property in order to save money; in reality, a fancier office space is useful for attracting recruits to the company.

For the same reason, it can be difficult to apply ABM to strategic thinking. The problem in this area is that a new strategic direction may be quite expensive in the short-term, but has prospects for a long-term payoff that are difficult to quantify under an ABM analysis.

For the two indicated reasons, the information generated by an ABM analysis cannot be used to drive all management decisions - it is simply information that can then be inserted into the general context of how an organization should be operated. Thus, it is one of several decision tools that management can use.

So, What is Business Process Reengineering?

Business process reengineering is the act of recreating a core business process with the goal of improving product output, quality, or reducing costs.

Typically, it involves the analysis of company workflows, finding processes that are sub-par or inefficient, and figuring out ways to get rid of them or change them.

Business process reengineering became popular in the business world in the 1990s, inspired by an article called Reengineering Work: Don’t Automate, Obliterate which was published in the Harvard Business review by Michael Hammer.

His position was that too many businesses were using new technologies to automatefundamentally ineffective processes, as opposed to creating something different, something that is built on new technologies.

Think, using technology to “upgrade” a horse with lighter horseshoes which make them faster, as opposed to just building a car.

In the decades since, BPR has continued to be used by businesses as an alternative to business process management (automating or reusing existing processes), which has largely superseded it in popularity.

And with the pace of technological change faster than ever before, BPR is a lot more relevant than ever before.

Business Process Reengineering Steps

As we’ve mentioned before, business process reengineering is no easy task.

Unlike business process management or improvement, both of which focus on working with existing processes, BPR means changing the said processes fundamentally.

This can be extremely time-consuming, expensive and risky. Unless you manage to carry out each of the steps successfully, your attempts at change might fail.

Step #1: Identity and Communicating the Need for Change

If you’re a small startup, this can be a piece of cake. You realize that your product has a high user drop-off rate, send off a text to your co-founder, and suggest a direction to pivot.

For a corporation, however, it can be a lot harder. There will always be individuals who are happy with things as they are, both from the side of management and employees. The first might be afraid that it might be a sunk investment, the later for their job security.

So, you’ll need to convince them why making the change is essential for the company. If the company is not doing well, this shouldn’t be too hard.

In some cases, however, the issue is with the company not doing as well as it could be. Meaning, you should do your research. Which processes might not be working? Is your competition doing better than you in some regards? Worse?

Once you have all the information, you’ll need to come up with a very comprehensive plan, involving leaders from different departments. The management will have to play the role of salespeople: conveying the grand vision of change, showing how it’ll affect even the lowest-ranked employee positively.

Risk of Failure: Not Getting Buy-In From The Company

If you fail to do this, however, your business process reengineering efforts might be destined to fail long before they even start.

Business Process Re-Engineering can seriously impact on everyone in the company, and sometimes this can appear to be a negative change for some. Some employees might, for example, think you’ll let them all go if you find a better way to function (which is a real possibility).

In such cases, even if the management is on board, the initiative might fail because the employees aren’t engaged.

Usually, it’s possible to get the employees buy-in by motivating them or showing them different views they weren’t aware of. Sometimes, however, the lack of employee engagement might be because of a bad workplace culture – something that might need to be dealt with before starting any BPR initiatives.

Step #2: Put Together a Team of Experts

As with any other project, business process reengineering needs a team of highly skilled, motivated people who will carry out the needed steps.

In most cases, the team consists of:

- Senior Manager. When it comes to making a major change, you need the supervision of someone who can call the shots. If a BPR team doesn’t have someone from the senior management, they’ll have to get in touch with them for every minor change.

- Operational Manager. As a given, you’ll need someone who knows the ins-and-outs of the process – and that’s where the operational manager comes in. They’ve worked with the process(es) and can contribute with their vast knowledge.

- Reengineering Experts. Finally, you’ll need the right engineers. Reengineering processes might need expertise from a number of different fields, anything from IT to manufacturing. While it usually varies case by case, the right change might be anything – hardware, software, workflows, etc.

Risk of Failure: Not Putting The Right Team Together

There are a lot of different ways to mess this one up.

If the team consists of individuals with a similar viewpoint and agenda, for example, they might not be able to properly diagnose the problems/solutions.

Or, the team might involve too many or too few people. In the first case, the decision making might be slowed down due to conflicting viewpoints. In the later, there might not be enough experts on certain fields to create adequate solutions.

It’s hard to put all that down as a framework, as it depends on the project itself. There is one thing, however, that benefits every BPR team: having a team full of people who are enthusiastic (and yet unbiased), positive and passionate about making a difference.

Step #3: Find the Inefficient Processes and Define Key Performance Indicators (KPI)

Once you have the team ready and about to kick-off the initiative, you’ll need to define the right KPIs. You don’t want to adapt to a new process and THEN realize that you didn’t keep some expenses in mind – the idea of BPR is to optimize, not the other way around.

While KPIs usually vary depending on what process you’re optimizing, the following can be very typical:

- Manufacturing

- Cycle Time – The time spent from the beginning to the end of a process

- Changeover Time – Time needed to switch the line from making one product to the next

- Defect Rate – Percentage of products manufactured defective

- Inventory Turnover – How long it takes for the manufacturing line to turn inventory into products

- Planned VS Emergency Maintenance – The ratio of the times planned maintenance and emergency maintenance happen

- IT

- Mean Time to Repair – Average time needed to repair the system / software / app after an emergency

- Support Ticket Closure rate – Number of support tickets closed by the support team divided by the number opened

- Application Dev. – The time needed to fully develop a new application from scratch

- Cycle Time – The time needed to get the network back up after a security breach

Once you have the exact KPIs defined, you’ll need to go after the individual processes. The easiest way to do this is to do business process mapping. While it can be hard to analyze processes as a concept, it’s a lot easier if you have everything written down step by step.

This is where the operational manager comes in handy – they make it marginally easier to define and analyze the processes.

Usually, there are 2 ways to map out processes:

- Flowcharts – the most basic way to work with processes is through flowcharts. Grab a pen and paper and write down the processes step by step.

- Workflow Software – if you’re more tech-savvy, using software for process analysis can make everything a lot easier. You can use Tallyfy, for example, to map out your processes, include user responsibilities, etc. Simply using such software might end up optimizing the said processes as it allows for easier collaboration between the employees.

Risk of Failure: Inability to Properly Analyze Processes

Or, to put it more succinctly – impatience. It’s uncommon for someone to try business process reengineering if they profits are soaring and the projections are looking great.

BPR is usually called for when things aren’t going all that well and businesses need drastic changes. So, it can be very tempting to hurry things up and skip through the analysis process and start carrying out the changes.

The thing is, though, the business needs analysis needs to be done properly, not rushed through to get to the more exciting parts.

There are always time and money pressures in the business world, and it’s the responsibility of the senior management to resist the temptation and make sure the proper procedure is carried out. Problem areas need to be identified, key goals need to be set and business objectives need to be defined and this takes time.

Ideally, each stage requires input from groups from around the business to ensure that a full picture is being formed, with feedback and ideas being taken into consideration from a diverse range of sources. The next step is to identify and prioritize the improvements that are needed and those areas and processes that need to be scrapped. Any business that doesn’t take this analysis seriously will be going into those next steps blind and will find that their BPR efforts will fail.

Any business that doesn’t take this analysis seriously will be going into those next steps blind and will find that their BPR efforts will fail.

Step #4: Reengineer the processes and Compare KPIs

Finally, once you’re done with all the analysis and planning, you can start implementing the solutions and changes on a small scale.

Once you get to this point, there’s not much to add – what you have to do now is keep putting your theories into practice and seeing how the KPIs hold up.

If the KPIs show that the new solution works better, you can start slowly scaling the solution, putting it into action within more and more company processes.

If not, you go back to the drawing board and start chalking up new potential solutions.

Business Process Reengineering Examples

The past decade has been very big on change. With new technology being developed at such a breakneck pace, a lot of companies started carrying out business process reengineering initiatives. There are a lot of both

There are a lot of both successful and catastrophic business process reengineering examples in history, one of the most famous being that of Ford.

BPR Examples: Ford Motors

One of the most referenced business process reengineering examples is the case of Ford, an automobile manufacturing company.

In the 1980s, the American automobile industry was in a depression, and in an attempt to cut costs, Ford decided to scrutinize some of their departments in an attempt to find inefficient processes.

One of their findings was that the accounts payable department was not as efficient as it could be: their accounts payable division consisted of 500 people, as opposed to Mazda’s (their partner) 5.

While Mazda was a smaller company, Ford estimated that their department was still 5 times bigger than it should have been.

Accordingly, Ford management set themselves a quantifiable goal: to reduce the number of clerks working in accounts payable by a couple of hundred employees. Then, they launched a business process reengineering initiative to figure out why was the department so overstaffed.

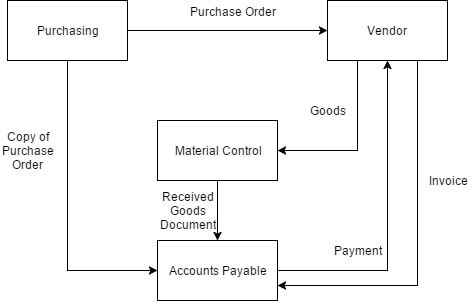

They analyzed the current system, and found out that it worked as follows:

- When the purchasing department would write a purchase order, they sent a copy to accounts payable.

- Then, the material control would receive the goods, and send a copy of the related document to accounts payable.

- At the same time, the vendor would send a receipt for the goods to accounts payable.

Then, the clerk at the accounts payable department would have to match the three orders, and if they matched, he or she would issue the payment. This, of course, took a lot of manpower in the department.

Old Payable Process

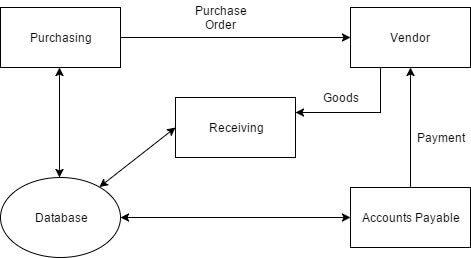

So, as is the case with BPR, Ford completely recreated the process digitally.

- Purchasing issues an order and inputs it into an online database.

- Material control receives the goods and cross-references with the database to make sure it matches an order.

- If there’s a match, material control accepts the order on the computer.

New payable process

This way, the need for accounts payable clerks to match the orders was completely eliminated.

https://y-sbm.com/blog/why-do-you-need-to-adopt-business-process-automation-software

ReplyDelete